Customer stories

Advanced engineering isn’t theory. It’s tested in the toughest projects. Trust, collaboration, and care turn challenges into progress. These are stories to prove it.

Data & AI

Brønnøysund Register Centre

BRC wanted to digitize many of their registers and use the data in new ways.Data & AI

-1.jpg?width=1080&height=725&name=pexels-alexis-b-1699196-340013792-2(3)-1.jpg)

Trollhättan Energi

Trollhättan Energi partnered with Twoday to develop a powerful, data-driven solution.Data & AI

Copenhagen Airports

From Legacy to Lakehouse: Driving data value and powering AI innovation with DatabricksCLOUD

VARD

Secure and scalable cloud service that meets strict cybersecurity and resilience standards.Data & AI

.jpg?width=2048&height=1365&name=pexels-ono-kosuki-6000169-2(1).jpg)

Arbejdernes Landsbank

A new data platform paves the way for a stronger, data-driven futureData & AI

Wattn

A future-proof digital platform that powers progress.Engineering

Finnish Food Authority

Successful development with design thinkingData & AI

The Danish Working Environment Authority

Effective collaboration paved the way for a successful IT modernization.Product

SCB

Secure authentication with e-identificationData & AI

N1

N1 collects data on their cable cabinets with N1GO!Cloud

The Danish Agency for Labour Market and Recruitment

Increased flexibility in IT infrastructure.AI

SEGES

Innovation creates the future of agriculture with AI and MLOpsCloud

Verdo

A modern integration platform unlocks new business opportunities.Data & AI

Spar Nord

A new platform puts Spar Nord in control.AI

Wellbeing services county of Päijät-Häme

Artificial intelligence streamlines social and health services.Data

ISS

Saving hundreds of hours by modernizing the data platform and customer reportingEngineering

Optimar

Optimar Commander - A game changer for the seafood industry.Data

VandCenter Syd

VandCenter Syd reduces ammonia emissions with machine learningEngineering

HUS

New system for managing patient and treatment guidelinesDigital Experience

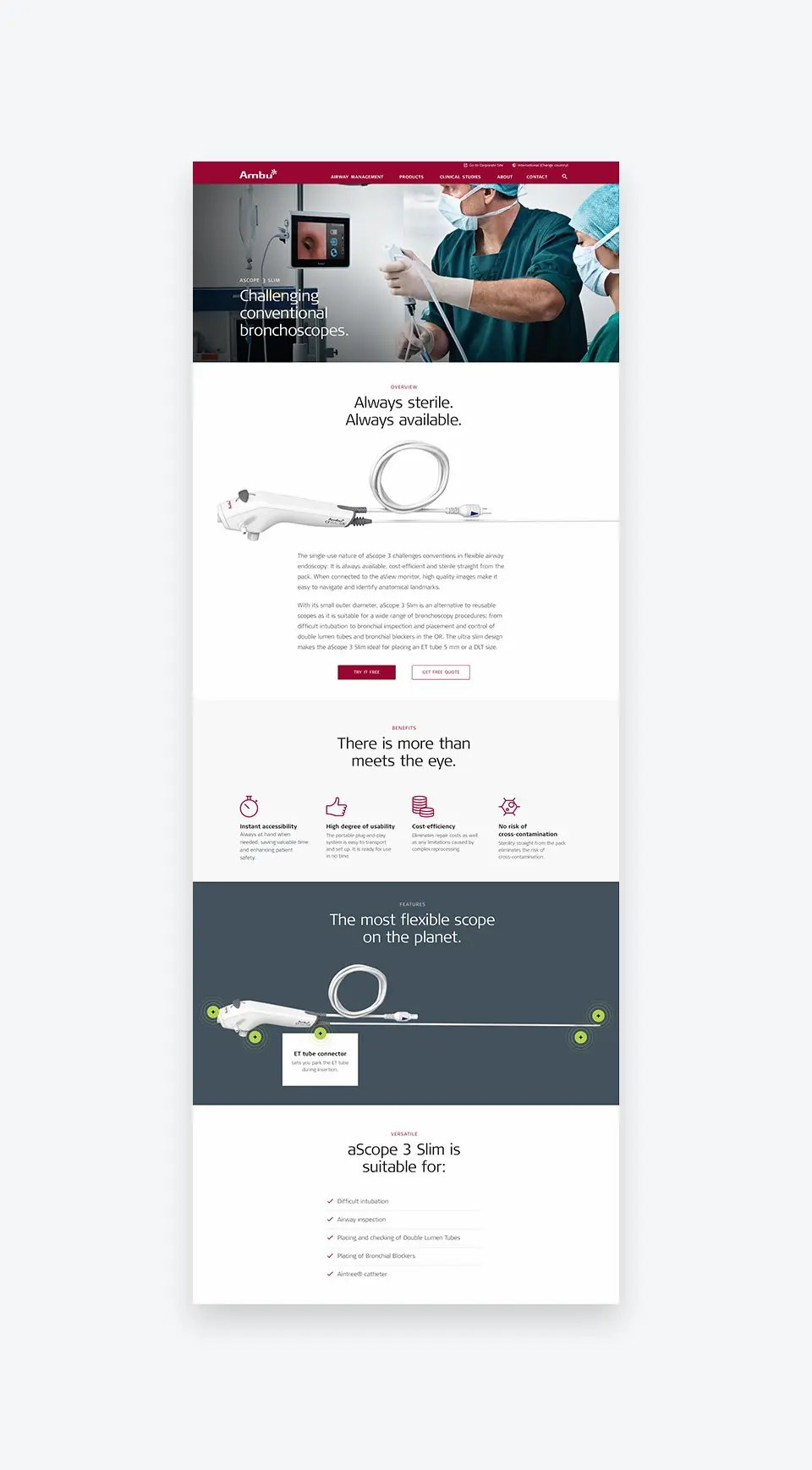

Ambu

A 46% traffic increase and (many) more warm leads.Engineering

Istekki

Building a better care relationship with the patient through the digitalization of servicesData

Anora

Fast tracking the development and implementation of a modern data platform.Data

Walki

Walki got better business planning and forecasting with AnaplanProduct

Normal

Digitizing the agreement process and GDPR complianceDigital experiences

Plantorama

An all-in-one LS Retail solution that creates better experiences for both customers and employeesDigital experiences

Bloomingville

An inspiring digital platform that strengthens the brand and boosts B2B and B2C salesDigital experiences

Innovation Living

Combining CMS and PIM into a single solution creates valueData

Pintos

Pintos wanted to centralize information and enhance data-driven management – Salesforce provided a scalable solutionData

Nuuday

Information Hub makes it easy to access reports at NuudayData

Wrist

Wrist is driven by data, analyzes and insightsEngineering

Agency for Digital Government

Groundbreaking new technology for public proofs of identificationData

Taksi Helsinki

Saving the environment and public funds with an optimization algorithmCloud

The Geological Survey of Finland

Nnew customer service model promotes sustainable growthData & AI

DENSIQ

Modernization of IT infrastructure strengthens data-driven decision-makingData & AI